GenAI in practice: Intelligent quality control on the production line.

CHALLENGE:

FMCG industry, specializing in dairy products packaged in plastic containers, faced challenges in quality control. Manual inspections were costly, time-consuming, and prone to errors due to subjective human assessments, leading to inconsistencies in the process. The company needed a solution to enhance product quality, reduce operational costs, and eliminate the risk of human error.

IMPLEMENTED SOLUTIONS:

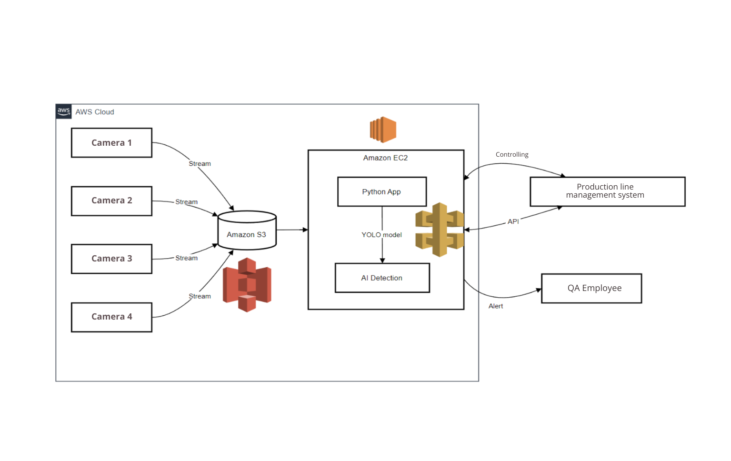

We developed a system based on GenAI and AWS, utilizing the YOLO model for real-time defect detection. Data stored in Amazon S3 enabled the simultaneous operation of four cameras across four production lines, while integration with the existing infrastructure allowed for the automatic removal of defective packages from the production line. The system ensures scalability and security, supporting the client’s further growth.

ACHIEVED EFFECTS:

The implementation of the solution reduced quality control time by half, lowered operational costs, and eliminated subjective errors. Automation allowed employees to focus on strategic tasks, contributing to increased production efficiency. Learn more about the project by downloading the case study.